Professional Injection Mould Maker

Join Date: 2021-04-13

In general, "auto mould" is the general term for the moulds used to manufacture all automobile parts. For example, injection moulds, stamping molds, forging molds, casting wax moulds, glass moulds, etc. The body of the car will appear in front of people When they talk about cars. In other words, the body is the identifying assembly of the car. The body represents the image characteristics of that car. In a narrow sense, automobile mould is the general name of the mould for punching all stamping parts on the automobile body. That is, "automobile body stamping die". For example, the top cover flanging die, the beam reinforcement plate pressing die, etc. The most important part of the automobile mould is the cover mould. This type of die is mainly a cold die. In general, "automobile mould" is the general term for the molds used to manufacture all parts of automobiles. For example, stamping moulds, injection moulds, forging molds, casting wax moulds, glass moulds, etc.

The stamping parts on the car body are roughly divided into cover parts, beam parts and general stamping parts. The stamping parts that can clearly express the characteristics of the car's image are the car cover parts. Therefore, the more specific automobile mould can be said to be "automotive cover stamping mould." Referred to as automotive panel die. For example, the front door outer panel trimming die, the front door inner panel punching die, etc. Of course, not only the car body has stamping parts. All stamping dies on automobiles are called "automotive stamping dies". In summary:

1. Automobile mould is the general name of moulds used to manufacture all parts of automobiles.

2. Automobile stamping dies are used to punch all stamping parts on automobiles.

3. Auto body stamping die is a die for punching all stamping parts on auto body.

4. Auto cover stamping die is a die for punching all cover parts on auto body.

The stamping parts on the car body are roughly divided into cover parts, beam parts and general stamping parts. The stamping parts that can clearly express the characteristics of the car's image are the car cover parts. Therefore, the more specific automobile mould can be said to be "automotive cover stamping mould." Referred to as automotive panel die. For example, the front door outer panel trimming die, the front door inner panel punching die, etc. Then, not only the car body has stamping parts, but also all l stamping dies on automobiles are called "automotive stamping dies". In summary:

1. Automobile mould is the general name of molds used to manufacture all parts of automobiles.

2. Automobile stamping dies are used to punch all stamping parts on automobiles.

3. Auto body stamping die is a die for punching all stamping parts on auto body.

4. Auto cover stamping die is a die for punching all cover parts on auto body.

There are many ways to classify automobile plastic molds. According to the different methods of forming and processing plastic parts, they can be divided into the following categories:

Injection mould

There are many ways to classify automobile plastic moulds according to the different methods of forming and processing plastic parts, they can be divided into the following types:

Injection mould

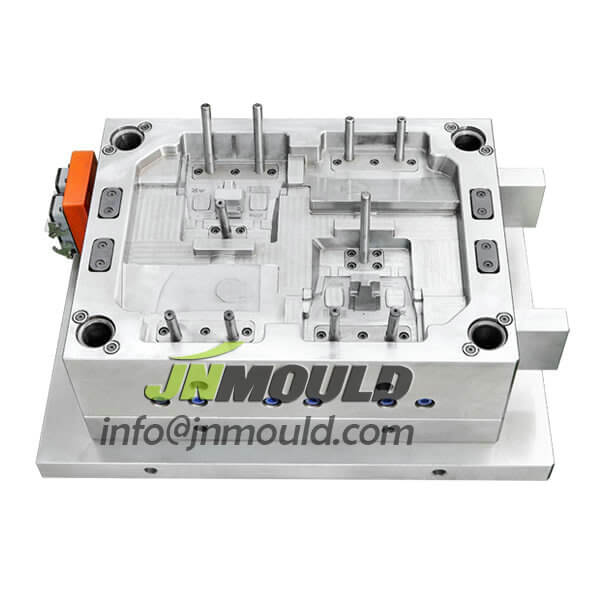

The moulding process feature of the injection mould is that the plastic raw material is placed in the heating barrel of the injection machine. The plastic is melted via heat, driven by the screw or plunger of the injection machine, enters the mould cavity through the nozzle and the pouring system of the mould, and the plastic is formed by heat preservation, pressure holding, and cooling in the mould cavity. Since the heating and pressurizing device can function in stages, injection moulding can not only mould plastic parts with complex shapes, but also has high production efficiency and good quality. Therefore, injection moulding occupies a large proportion in the moulding of plastic parts, and injection moulds account for more than half of plastic moulding moulds. Injection machines are mainly used for the moulding of thermoplastics, and in recent years have gradually been used for the moulding of thermoset plastics.

Compression mould

Compression mould is also called compression mould or compression mould. The moulding process of this mould is characterized by adding plastic raw materials directly into the open mould cavity, and then closing the mould. After the plastic is in a molten state under heat and pressure, the cavity is filled with a certain pressure. At this time, the molecular structure of the plastic has a chemical cross-linking reaction, which gradually hardens and sets. Compression moulds are mostly used for thermosetting plastics, and their moulded plastic parts are mostly used for the shells of electrical switches and daily necessities.

Transfer mode

Transfer mould is also called pressure injection mould or extrusion mould. The moulding process of this mould is characterized by adding plastic raw materials into the preheated feeding chamber, and then pressure is applied to the plastic raw materials in the feeding chamber by the pressure column. The plastic is melted under high temperature and high pressure and enters the cavity through the casting system of the mould. The chemical cross-linking reaction occurs and gradually solidifies and forms. The transfer moulding process is mostly used for thermosetting plastics, which can form plastic parts with more complex shapes.

Extrusion die

The extrusion die is also called the extruder head. This kind of mould can continuously produce plastics with the same cross-sectional shape, such as plastic pipes, rods, and sheets. The heating and pressurizing device of the extruder is the same as that of the injection machine. The plastic in the molten state will form a continuous moulded plastic part through the machine head, and the production efficiency is particularly high.

In additional, the several types of plastic molds listed above, there are also vacuum forming moulds, compressed air moulds, blow moulds, low-foaming plastic moulds, and so on.

The stamping parts on the car body are roughly divided into cover parts, beam parts and general stamping parts. The stamping parts that can clearly express the characteristics of the car's image are the car cover parts. Therefore, the more specific automobile mould can be said to be "automotive cover stamping mould." Referred to as automotive panel die. For example, front door outer panel trimming die, front door inner panel punching die, etc.

No.13, Maofeng Street, West Industry Zone, Huangyan, Taizhou, Zhejiang, China.

318020

0086-576-84352158 / 0086-15057227888

info@jnmould.com

Friendly Links : Alibaba Pallet Mould China Mould Injection Mould Chair Mould

Copyright © Jnmould 2019. All rights reserved.