Professional Injection Mould Maker

Join Date: 2020-08-18

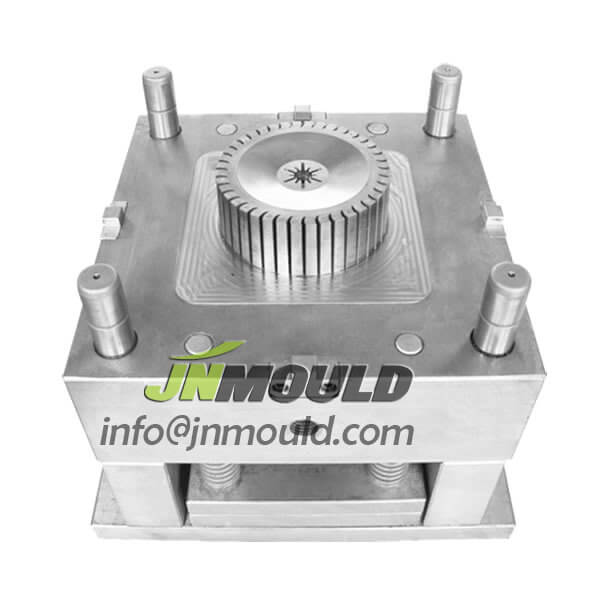

As a China home appliance mould manufacturer, Jnmould has completed a number of projects for home appliance mould. We use advanced 2D and 3D software to build complex plastic products. In this process, we choose the most appropriate processing equipment and processing methods, in order to manufacture high-quality appliances mould. We guarantee the accuracy and accuracy of plastic moulds used in the manufacture of home appliances. In order to meet the requirements of different processing and mould life, a variety of high-quality mould steels are used to manufacture home appliances moulds.

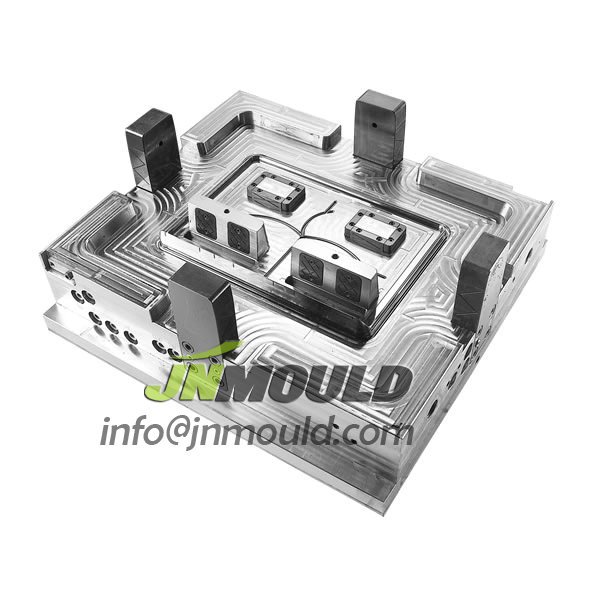

Jnmould plastic product design team is specialized in the design of various for home appliance moulds, providing a full set of design services, and has many years of experience in the field of various types of mould manufacturing. Our wide range of home appliance moulds will be your needs to provide the best solutions. Making moulds for home appliances is a difficult task because the plastic components have to fit perfectly with the rest of the assembly. So Jnmould made sure we listened patiently to our customers and worked out all the details before going ahead with production.

Our home appliance moulding technology advanced and excellent quality, can ensure high-quality products. Jnmould is a supplier and manufacturer of a large number of moulds in the home appliance industry. We have made many moulds for refrigerators, air fans, air conditioners, televisions, etc. We have imported a number of advanced large precision processing equipment for the production of household appliances mould. In addition, we have built complete CAD, CAM and CAE systems to ensure high precision of moulds.

Jnmould adopts high-speed processing, generally used in large household appliance cover mould, the surface processing precision can reach 0.01mm. High-speed milling and finishing of die surface can be used with only a small amount of polishing to save a lot of grinding and polishing time. High-speed machining significantly shortens the forming cycle and improves the market competitiveness of products.

Jnmould adopts hot runner technology, proper hot runner system ensures perfect melt flow in the mold and reduces plastic waste. We have been able to successfully use gas-assisted technology on TV housings, washing machine housings and moulds for thick-walled plastic parts. Gas-assist injection moulding has the advantages of low injection pressure, small warping deformation and good surface quality, which can greatly reduce the cost under the premise of ensuring product quality.

No.13, Maofeng Street, West Industry Zone, Huangyan, Taizhou, Zhejiang, China.

318020

0086-576-84352158 / 0086-15057227888

info@jnmould.com

Friendly Links : Alibaba Pallet Mould China Mould Injection Mould Chair Mould

Copyright © Jnmould 2019. All rights reserved.