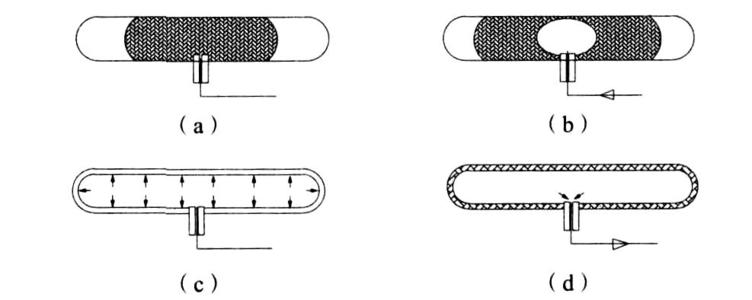

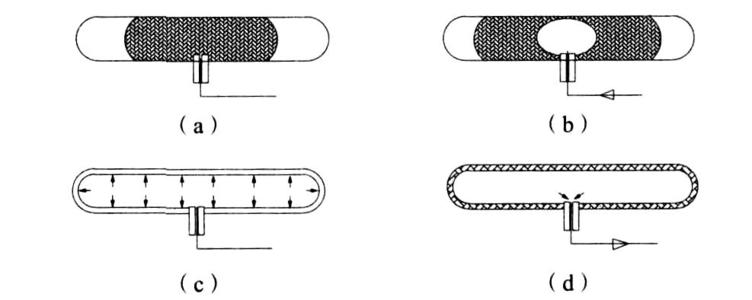

Gas assisted injection mold technology, mainly in the traditional injection molding process, first injected a fixed amount of molten resin, and then high pressure nitrogen quickly injected, using gas to quickly and effectively continue to promote the molten resin to fill the cavity, and continue to maintain the gas pressure, until the product molding.

Using gas-assisted molding technology, the mold is manufactured in the same way as the ordinary mold (but to consider the location of the airway and the gas needle, there can be multiple air intakes and exhaust ports); But the product structure of plastic parts is very different from the conventional one, and it is necessary to pay attention to the time difference between glue and air intake when forming. The air inlet is connected with the gas auxiliary equipment, and the air outlet can directly discharge the gas out of the mold (or enter the air from the glue inlet, without exhaust port). The die gate should be selected at the end of the product as far as possible. The temperature of the gas auxiliary die is high, and the hot runner is generally used. The overflow groove in the gas-assisted mold should be tapered so that it is convenient to take it out.

Advantages of

gas assisted injection:

1. can design ultra-thick parts and very few contraction marks.

2. The weight is 50% lighter than the product with the same appearance; Save materials.

3. parts forming cycle is short (nitrogen can play a cooling role, and from the parts of the internal cooling, cooling uniform, good effect).

4. Small deformation after forming shape, small internal stress after forming parts; And the strength of parts and structure can be greatly improved.

5. Gas auxiliary is generally nitrogen converted from high pressure liquid nitrogen, so it can be directly discharged.

Application of gas-assisted technology:

At present, gas-assisted injection molding process is widely used, such as daily plastics for daily use, automotive plastic parts and industrial supplies, etc. Such as small household appliances handle, car door handle handle; There are some gas - assisted chairs, steam - assisted car door guard plate, etc.

JNMOULD gas - assisted injection molding is widely used, can form a variety of types of injection parts. We have decades of plastic mold manufacturing experience, in plastic molding technology, we can always provide customers with the best solutions.