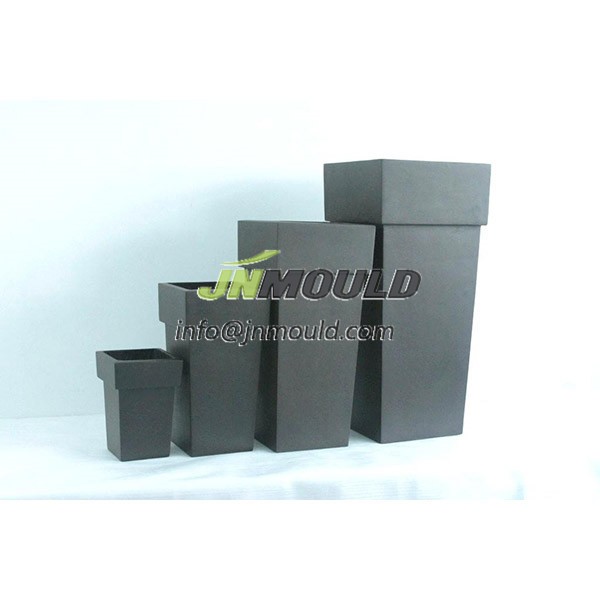

flower pot mould

Flower pot moulds have great development prospects in the future. Because of the modern people's lifestyle, flower cultivation has become their hobby in their lives. Flowerpot moulds bring economic benefits. A pot of flowers may have a profit of 70%, but if a flower pot is added, their overall profit maybe 120%.

Jnmould is known as one of the best flower pot mould manufacturers in China, we offer entire plastic flower pot moulding solutions. Customers can customize the flower pot shape, size and material types... Jinnuo will conduct flower pot mould design and professional moulding processing, production and test. With advanced moulding technology, our flower pot moulds are mainly exported to North America, South America, Europe, Australia and Middle East countries.

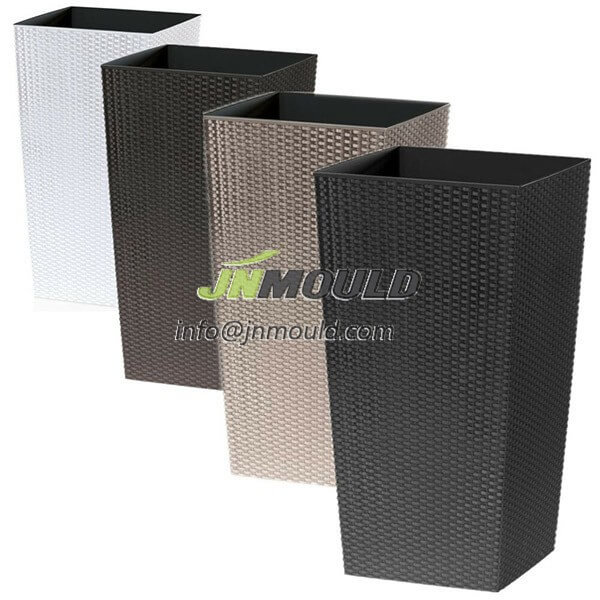

Most flower pot moulds are very simple in mould structure. The appearance of the flower pot mould can be made into a mirror surface, it can also be made as a dermatoglyphic, and the company logo can also be added by thermal transfer. Jnmould will manufacture the different flower pot in different plastic material, like PP, PE, ABS, Melamine resin, etc.

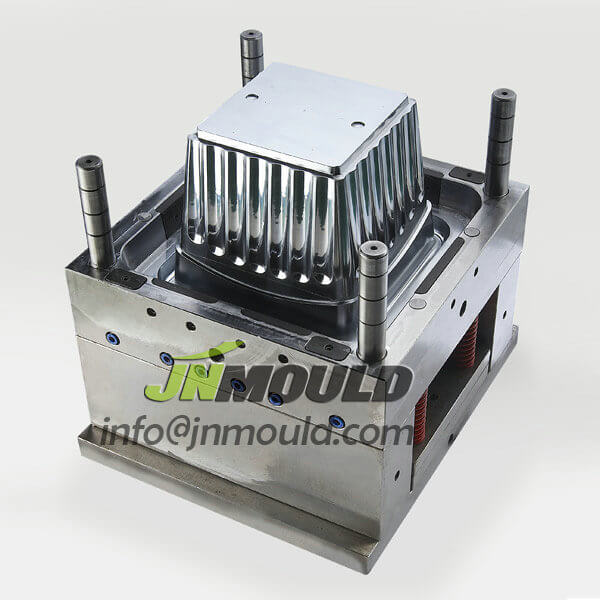

Flower pots are produced by injection moulds, with short production cycles, large output, and long mould life. Flower pot injection moulding is a manufacturing process in which the resin in the barrel is heated to a molten state and then injected into a flower pot mould to moulding a mould-shaped flower pot. It starts with plastic granulate and is fed into the injection moulding machine, where the plastic is melted. The molten plastic enters the mould cavity through the gate and runner system. The mould is kept at the set temperature, so the plastic flower pots can be formed almost after a filling is complete. After that, the flower pot mould is opened and the ejector pins push the flower pot out of the mould. Then, the mould is closed again for the next production. Advanced flower pot mould processing technology enables us to accurately control your cost and mass-produce the most suitable flowerpot products. Besides, we will choose the right injection moulding machine to meet your high-speed production needs.

Flower pot mould manufacturer

Since its establishment in 2003, Jinnuo is a well-known plastic flower pot manufacturer and plastic flower pot mould factory in China. It is committed to professionally producing various plastic planting moulds, such as PET, PP plastic flower pot mould, round flower pot mould, and rose flower pot mould, plastic garden pot mould, etc. If you are interested in flower pot mould, please contact us.

- 1. Superb craftsmanship: combining modern technology (CNC & EDM machine, milling machine, engraving machine, etc.).

- 2. Reasonable mould structure design: drawings are designed by our experienced engineers.

- 3. Injection mould operation: fully automatic high-speed injection

- 4. Equipment: CNC, EDM